Welding electrode selection is a quite challenging decision because we need to consider many factors while choosing an electrode for a specific project/product. In this post, we discuss the factors which are responsible for choosing an electrode for Shielded Metal Arc Welding Process (SMAW) for carbon/manganese steels. The Shielded metal arc welding is also known as Manual Metal Arc Welding (MMAW). The electrodes for the SMAW/MMAW process are always covered by flux, therefore, known as covered electrodes or coated electrodes. Welding electrodes are identified by classification number (AWS Electrode Classification Number), it starts with E followed by either a four-digit number or a five-digit number such as E7018, E6010, E6013, E10018, etc.

Mandatory Classification Designators

The electrode classification numbers are not just for identification each letter and digit have a specific meaning;

example: E7018

The alphabet ‘E’ stands for Electrode

First two digits (three digits in 5-digit electrodes) denotes the minimum tensile strength of deposited weld metal

In our case “70” means 70ksi (or 70000psi) tensile strength.

The third digit (fourth digit in 5-digit electrodes) indicates the welding position in which the electrode can be used.

In our case “1” means this electrode can be used in all weld positions.

The last two digit shows the flux composition, current type, and polarity of the electrode.

In our case “18” means basic flux (low hydrogen) current can be AC or DCEP (Alternate Current / Direct Current Electrode Positive)

Optional Supplemental Designators

We can find in the oil&gas industry an electrode may have additional numbers after it, a good example is "E8018-B2H4R".

In this case, the "B2" indicates the chemical composition of the weld metal deposit.

The "H4" is the diffusible hydrogen designator, which indicates the maximum diffusible hydrogen level obtained with the product is 4ml in 100g of deposited weld metal.

The "R" stands for the moisture-resistant designator to indicate the electrode's ability to meet specific low moisture pickup limits under controlled humidification tests

Before selecting an electrode as we discussed earlier, we need to consider the following factors which will affect the feasibility, quality, and cost of the product.

1. Parent Metal / Base metal2. Position of Weld3. Power Supply4. Preparation of Joints5. Weld Quality and Finish6. Cost of Weld (Must be as low as possible)

1. Parent Metal: Parent Metal or Base Metal is the most important among the above. The following three parameters of parent metal must be taken for consideration;

Mechanical properties: The mechanical properties especially the tensile strength of the parent metal and electrode should be similar or as close as possible. Extensive differences in tensile strength between the welding electrode and the base metal, there will always be chances of cracking and or other weld discontinuities. Hence to prevent cracking and other weld discontinuities we should choose an electrode having minimum tensile strength equivalent to the parent metal being welded. (The tensile strength of the welding electrode shall not be less than base metal)

Chemical Properties: The chemical properties shall also be checked before choosing an electrode. The electrode chemical composition should match the chemical composition of the base metal, especially the carbon percentage.

Thickness: Base metal thickness is very important while choosing an electrode. For thinner materials, an electrode with soft arc and less penetrating power can give good results but for thicker material we need and electrode with digging arc for deep penetration, maximum ductility and low hydrogen for defect-free welding.

We must always remember that the electrode size (diameter) should not exceed the thickness of the parent metal.

2. Welding Position: The second factor is the weld position. All electrode classifications are not suitable for all weld positions. Each electrode is meant for welding at some particular position. Therefore, we need to choose the electrode as per the position of our job. The welding position is specified in the electrode number itself. As explained above we will get a number from the electrode classification. Refer the number with below given general summary of the welding position table which is prepared based on AWS A5.1 Table 1. Electrode classification.

3. Power Supply: Based on the flux composition of electrodes current type and polarity varies electrode class to class. Some electrodes can be used with alternating Power (AC) supply, some can be used with direct current power (DC) supply and some can be used in both. Depending upon the available power supply (Welding Machine) we can choose the electrode. However, the welding machines are available various range of power supply such as AC, DC and AC/DC in the market.

When using Direct Current power supply, if the electrode is connected with the positive terminal of the machine then it is known as Direct Current Electrode Positive (DCEP) or Reverse Polarity and, if the electrode is connected with the negative terminal of the machine then it is known as Direct Current Electrode Negative (DCEN) or Straight Polarity.

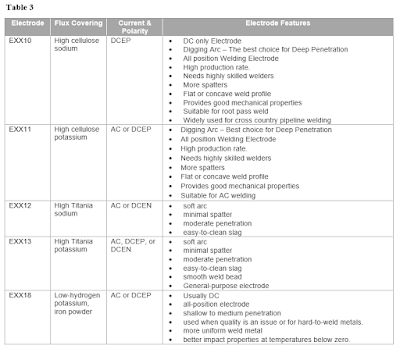

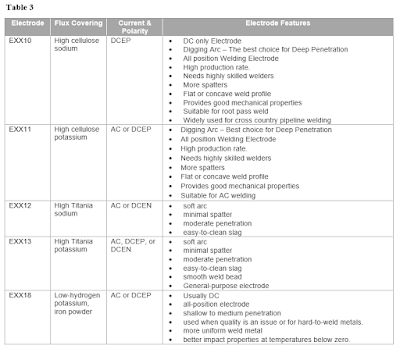

The last two digit of an electrode classification number represents the current type, polarity as well as flux composition of the electrode. Please refer below table which is prepared based on AWS A5.1 Table 1 for a summary of the electrode, flux coating, current type, and polarity in which they can be used.

4. Joint Preparation: The fourth factor to be considered while selecting an electrode is the joint preparation or groove configuration. If there is a tight fit-up or unbevelled root face (square butt weld joint) then an electrode with a digging arc can be used, which can provide deeper penetration. Electrodes such as E6010 or E6011 can be used for this purpose. If there is sufficient root gap and root face (single or double “V” groove weld joint), then we can use electrodes which can give shallow to moderate penetration electrodes such as E6013 or E7018.

5. Welding Quality/Weld finish: The required quality and the weld finishing is also an important factor to be considered before selecting an electrode. Electrodes can be chosen depending upon the final finishing requirement for example Flat weld bead, concave weld bead or convex weld bead. The quality of the weld must suit the service requirements of the product. For example, to weld cryogenic vessel parts that are supposed to work at extremely low temperature and pressure with high impact loading or parts that are subjected to a corrosive atmosphere, we need a low hydrogen electrode such as E7018, which can produce very sound welding with higher ductility. So, the chances of getting any failure due to weld defects during operation will be minimized or can be eliminated. The below table gives a summary of commonly used welding electrodes features, which you may find useful while selecting an electrode for a specific project/product.

6. Welding Cost: Cost is the most influenced factor in welding electrode selection. The electrode in which being to choose must fulfill the requirements of your project/product and at the same time, it must be cost-effective. We cannot choose the costly electrode for a low budget project. Similarly, for critical jobs where quality needs to be given the highest care a low hydrogen electrode with higher ductility such as E7018 can be considered. Always keep in mind the term “fitness for purpose” also the quality means compliance with the minimum requirement of the product. So, don’t choose the highest electrode in the segment. Choose always “cheap and best”.

Tags: Welding Electrodes, Selection of Electrode, Consumables for SMAW, Consumables for MMA Welding, Stick Welding Electrodes, Welding Consumables